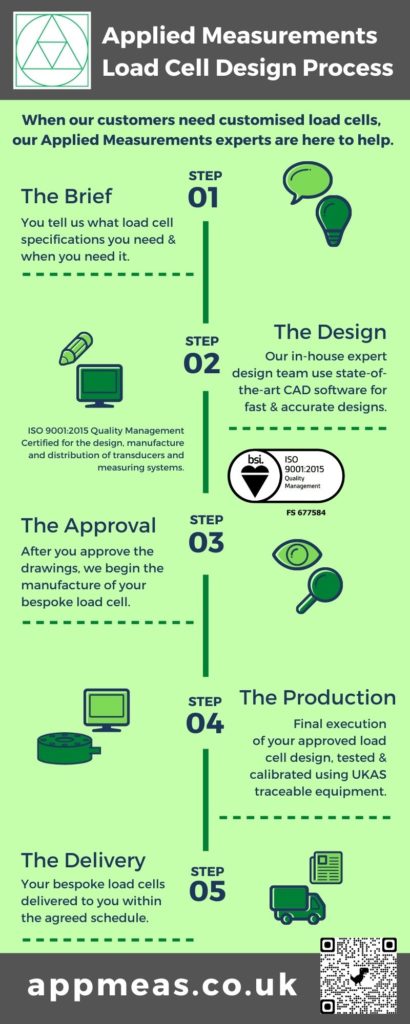

Do you need a unique load cell design for your application? How about an exact replacement for your existing one? See our 5 steps of our easy load cell design process.

Category: Load & Force

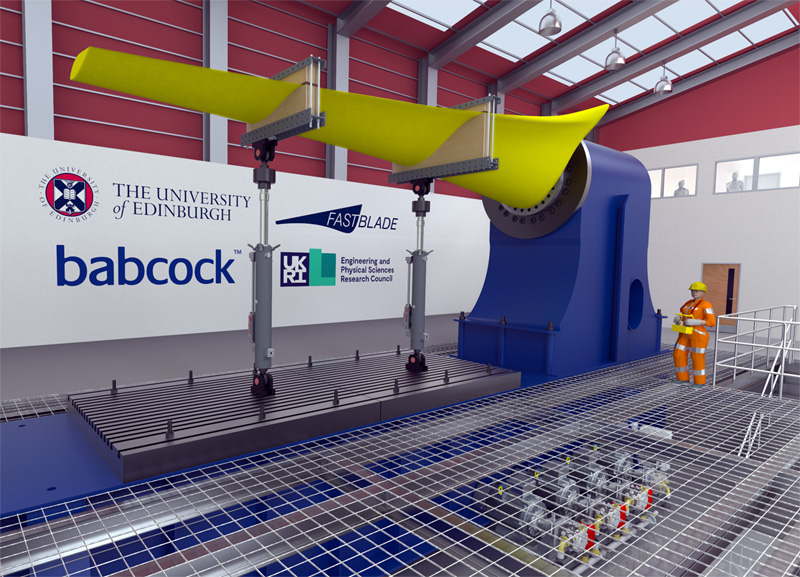

Applied Measurements Load Cells in World’s First Regenerative Fatigue Test Facility

Developed by the University of Edinburgh, FASTBLADE is designed for high-quality, low-cost fatigue testing of tidal turbine blades, composite bridge sections and carbon fibre aircraft wing boxes and is the world’s first test facility that uses regenerative hydraulic technology.

Thanks to its cost-effective and accelerated testing, FASTBLADE reduces design risks, delivers rapid evaluation and enables faster certification and deployment of new products to the global market.

Applied Measurements DSCC precision pancake load cells are an integral part of FASTBLADE’s design. They are low profile, high accuracy and have a high-frequency response.

Find out more…

5 Reasons This May Be the Best Load Cell for Plate Bearing Tests

Micro Geotechnical, an in-situ testing company, needed to accurately monitor the bearing capacity of the ground under a given load, to determine the safe bearing capacity of the soil.

The measuring instruments would need to be accurate and precise, with the ability to withstand the harsh outdoor environments of their in-situ plate bearing tests.

So, we offered them Applied Measurements button load cell CBES and our handheld indicator and here’s why…

New smallest button load cell ever made by Applied Measurements

Key features:

- Tiny Ø9mm and 2.9mm height

- Capacities from 0-10N up to 0-250N

- Accuracy: <±0.25% of rated capacity

- Wide operating temperature range: -40 to +125 °C

- Strain gauge based technology

- 2m cable as standard

- Integral load button

Applied Measurements new micro button load cell CDFT has a tiny 9mm diameter and 2.9mm height for accurate compression force measuring in the tiniest of spaces. It utilises state-of-the-art strain gauge technology combined with precision CNC machining to give you precise and reliable force measurement results.

Complete Force Measurement Systems Available in Just 7-10 Days

- Ready to use straight out of the box

- Supplied with sensor & instrumentation ready calibrated

- Available in 7 – 10 working days

- Ready for when you return to work

- Fast & easy installation

- Outstanding aftersales service – just give us a call

- 3 years warranty

How to measure grip strength of an eagle for BBC Natural World

Last year, we were asked to design a sensor to measure the grip strength of a golden eagle named Tilly, for the award-winning BBC documentary series, Natural World.

Challenge – to find a load cell that could withstand the estimated grip strength of an eagle.

As Tilly had been trained to catch and grip a tennis ball, the load cell needed to be small enough to fit inside a similar-sized measuring device yet withstand Tilly’s tremendous grip strength.

Thanks to their unique design, our DBBSMM miniature s-beam load cells were ideal for the job. Not only are they very compact but their s-shaped design offers superior side-load rejection and high accuracy.

Load cells deliver high accuracy in Gemini Telescopes even after 20 years!

20 years ago, we were approached by The Royal Greenwich Observatory in Cambridge to design and build nearly 700 bespoke load cells for two 8.1m diameter telescopes known as The Gemini Project.

Now 20 years on, these custom-made load cells are still consistently and accurately performing an integral part of the telescope’s control system.

To continue to deliver accurate and detailed astronomical images, we have been asked to re-design and manufacture custom load cells to the same specifications incorporating up-to-date electronics with the latest state-of-the-art amplifiers.

See how we did it.

Universal Fabric Tension Tester for All Fabrics and Styles

The Challenge – Accurately Measure Fabric Tension on Any Style of Furniture.

Fabric strength testing guarantees the fabric being used on furniture meets the high quality needed for durability, comfort and support.

Choosing the wrong type of fabric can lead to fabric tearing, loss of customer satisfaction and a decrease in sales and profit.

Find out how our miniature s-beam load cell, intuitive4-L digital indicator and industrial LVDT displacement sensors were used to determine fabric strength.