LVDT displacement sensors (or position sensors) by Applied Measurements are based on various technologies including LVDT (linear variable differential transformer), strain gauges and rotary potentiometers, known as ‘String Pots’. An LVDT displacement sensor is a transducer that measures displacement in a linear motion.

Our displacement sensors come with a variety of configuration options making them ideal for OEM applications. Plus, we can offer high-temperature versions and fully submersible versions. Accurate measuring ranges from a fraction of a millimetre up to 40 metres are available.

What is an LVDT Displacement Sensor?

Product Links

Filters

Availability

Output

Environment

Displacement Range

Key Features

Amplified Strain Gauge Displacement Sensor | AML/SGDA

0-5mm to 0-100mmFrom £553Buy OnlineIndustrial LVDT Displacement Transducer | Position Sensor | AML/IE

±0.5mm to ±500mmFrom £234Buy OnlineStrain Gauge Displacement Sensor | Linear Position Sensor | AML/SGD

0-5mm to 0-100mmFrom £425Buy Online

What is an LVDT?

The LVDT Operating Principle

The Linear Variable Differential Transformer (LVDT) or displacement sensor is an electromechanical transducer that converts the linear motion of the object to which it is coupled mechanically in a corresponding electrical signal.

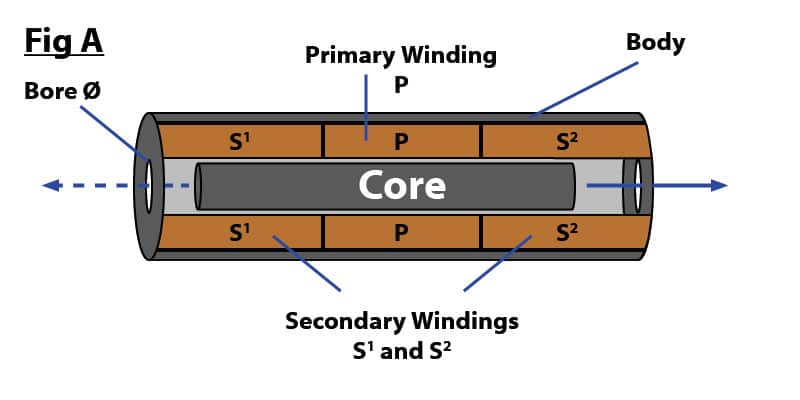

The basic design consists of a cylindrical array with a primary winding centred between two identically-wound secondary windings. The coils are wound on a hollow glass-reinforced polymer (GRP) former, which is surrounded by a high permeability magnetic shield. This assembly is then secured into a stainless steel tube that is sealed at both ends. This tubular element is the static part of the LVDT construction.

How Does an LVDT Displacement Sensor Work?

The moving part of an LVDT displacement sensor is a separate short rod of magnetically permeable material called the core. The core is free to move within the hollow bore of the coils and is mechanically coupled to the item being displaced (Figure A). One of the major benefits of the LVDT design is that there is no physical contact between the core and the coils. This gives the LVDT a hugely extended operating life.

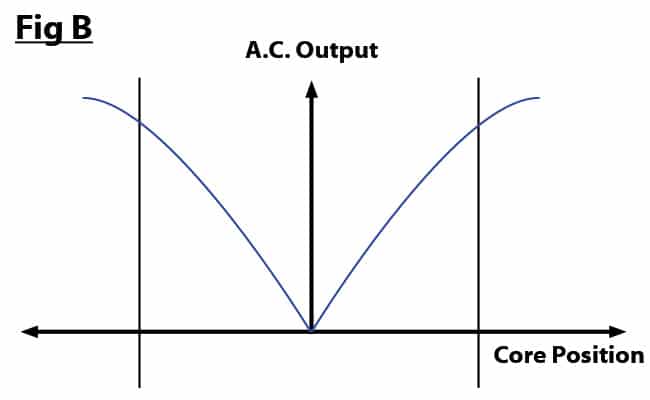

The primary winding (P) is energised with a constant amplitude a.c. supply at a fixed frequency anywhere between 1kHz and 10kHz. This produces an alternating magnetic field in the central winding which induces a signal into the secondary windings S¹ and S² depending on the position of the core (Figure B).

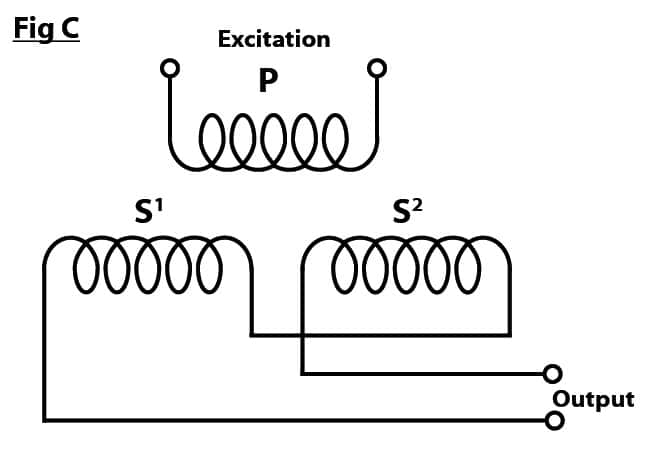

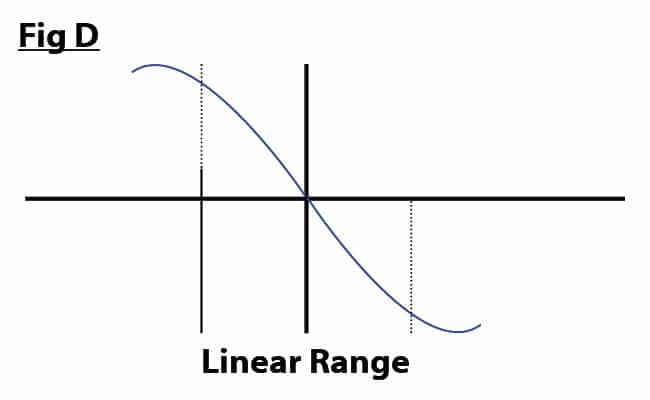

The output signal is the differential a.c. voltage between the two secondary windings which varies according to the position of the core within the coil (Figure C). When the core is positioned in the centre the output signal is zero, this is known as the null position. As the windings are precisely wound, the signal output has a linear relationship with the physical position of the core (Figure D).

Separate instrumentation is available to externally process the resultant a.c. voltage from the secondary coils into a d.c voltage or current and can also include a digital display. Alternatively, displacement sensors can incorporate a circuit that provides oscillation, demodulation and signal conditioning. These are referred to as DC/DC LVDTs as they require a simple DC supply and output either a d.c. voltage or current proportional and in phase with the position of the core.

Benefits of LVDT Displacement Sensors

Why use an LVDT? One of the main benefits of an LVDT is that there is no physical contact between the core and the coils (see Figure A). It is frictionless and there is no rubbing of mechanical parts. This gives the LVDT a long operating life. LVDTs are known for their high accuracy and excellent repeatability.

- Frictionless

- No Rubbing

- No Wearing of Mechanical Parts

- Long-Operating Life

Configurations & Options of LVDTs

The LVDT design can be easily adapted to fulfil a broad range of applications in research and industry. Some typical variations include:-

- Complete sealing for partial or full submersion in liquids and gases.

- Heavy-duty construction for use in harsh environmental conditions.

- Miniature and low-cost models for price-sensitive OEM applications.

- High-temperature applications to 150°C.

How to Choose an LVDT

There are many factors that can determine how to choose an LVDT for your application.

- Measurement Range

- Environmental Conditions

- Appropriate Type i.e. AC or DC, single-ended or double-ended, in-line…

- Accuracy and Resolution

- Linearity and Repeatability

- Output options

- Power Requirements

- Budget

Video of LVDT Displacement Sensors from Applied Measurements

Submersible LVDT Displacement Sensors

The Applied Measurements AML/IE Series Industrial LVDT Displacement Sensor in IP68 waterproof format is suitable for submersion to depths of up to 50 metres or external pressurisation to 5bar. Customised versions are available for applications where the LVDT is required to operate at greater depths.

Seawater & Harsh Environment LVDT Displacement Sensors

For harsh environments where LVDTs will be subjected to aggressive media such as seawater, fuels and chemicals, the AML/IE Series Industrial LVDT Displacement Sensor by Applied Measurements can be supplied with alternative case and extension rod materials such as 316L Stainless Steel or Duplex Stainless Steel and PTFE cable to provide a highly corrosion-resistant sensing device.

Hazardous Area Displacement & Position Measurement

If you need to locate a displacement sensor or position sensor within a hazardous area, our AML/SGD series of strain gauge-based displacement sensors offers a relatively low-cost option when used in conjunction with a pair of Zener Barriers. Whilst it is not ATEX certified, it is a non-energy storing device and can, therefore, be classified as ‘Simple Apparatus’. Subject to acceptance by the specifying engineer, they can be used within a hazardous area without certification.

Applied Measurements can also supply signal conditioning, amplification and display/indication equipment to accompany our AML/SGD strain gauge displacement sensor which is suitable for use in the safe area. If hazardous area electronics are required please contact us to discuss your requirement.

Monitran Limited

Applied Measurements models AML/M, AML/E and AML/IE model LVDTs are manufactured in the UK by Monitran, for whom we are the appointed UK distributor. In addition to LVDTs, Monitran also manufactures a full range of accelerometers and vibration sensors along with associated instrumentation and monitoring systems. Visit their website monitran.com for further information.