This product has been discontinued.

Please use our Industrial Mid Range Draw Wire Displacement Sensor | P96 instead.

At a Glance

- Measuring Ranges: 0-100mm to 0-3000mm

- Outputs: 4-20mA, 0-10Vdc, R1K or SSI

- Environmental Protection: IP67

- Accuracy: <±0.1%/FS

- Optional <±0.05%/FS Accuracy

- Ideal for use in Harsh Heavy-Duty Industrial Environments

- Protected from Immersion to 1 metre for up to 30 mins and Totally Dust Tight

- Stainless Steel Housing for Tough Applications

- Excellent Shock and Vibration Resistance

- Higher Accuracy Versions Available for Precision Applications

- Fast and Simple Installation with its Compact Design

Description

The WS12 heavy duty draw wire displacement sensor range is designed to allow position, displacement or length measurement in harsh, heavy duty industrial applications and is available with ranges from 0-100mm and 0-3000mm.

The precision potentiometer sensing element used in the WS12 draw wire displacement sensor offers superb accuracy with linearity better than 0.1%/FS coupled with excellent resistance to shock and vibration.

An R1K potentiometer output is provided as standard from the WS12 heavy duty draw wire displacement sensor, while the option of integral signal conditioning to 0-10Vdc, 4-20mA or a digital SSI output is available if preferred. User-adjustable 0-10Vdc and 4-20mA output versions are also available.

Installation of the WS12 is fast and simple, while the compact IP67-rated aluminium and stainless steel housing provide protection against the toughest industrial environments.

Typical applications for the heavy duty draw wire position sensor include renewable energy system development & control, vehicular measurements and hydraulic systems.

Technical Specifications

Product Dimensions

Dimensions are in mm

| Measuring Range (mm) | A | B (ADSI16) | C | D | E | F (F*) |

|---|---|---|---|---|---|---|

| 0-100, 0-500, 0-1000 | 18.5 | 112 (137) | 14 | 43 | 71 | 141 (149) |

| 0-125, 0-1250 | 15.0 | 112 (137) | 14 | 43 | 71 | 141 (149) |

| 0-1500 | 11.0 | 127 (152) | 14 | 43 | 71 | 141 (149) |

| 0-2000 | 22.0 | 127 (152) | 15 | 79 | 109 | 182±3 (187) |

| 0-2500 | 13.5 | 127 (152) | 15 | 79 | 109 | 182±3 (187) |

| 0-3000 | 9.5 | 127 (152) | 15 | 79 | 109 | 182±3 (187) |

Case Studies

Our Shear Pin Load Cells and Draw Wire Sensors Deliver Flawless Results in Sub-Zero Temperatures

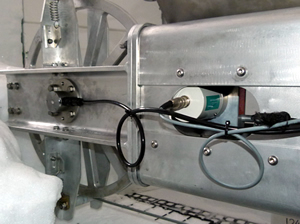

Applied Measurements were contacted by Victoria University of Wellington to provide reliable and accurate equipment that could operate in the sub-zero temperatures of the Antarctic. Using Applied Measurements’ two customised DBEP shear pin load cells, a WS12 draw wire sensor and four intuitive2 displays, the RICE team were able to successfully extract a 763m deep ice core from an ice cap on Roosevelt Island.

Load Pins and Position Sensors used for Antarctic Research

Applied Measurements needed to design and manufacture a pair of custom load pins for the university that could compensate for temperatures as low as -30degC. The load pin also had a built in ICA4S amplifier that could give a 4-20mA output for them to use to monitor the drilling forces.

Why Applied Measurements?

- Suppliers of top quality strain gauge sensors and transducers to every corner of industry - UK and worldwide

- Over 100 years of expert transducer knowledge

- Our high quality products all come with a 3 year warranty

Popular Products

Platform Load Cell | Single Point Load Cell | 0-250g to 0-40kg | OBUG

0-250g to 0-40kgFrom £128Universal Load Cell | Universal S-Beam Force Sensor | DBBSM

0-1kg up to 0-30,000kgFrom £254Buy OnlineHandheld Load Cell Indicator | Digital Display | TR150

From £308Buy OnlineStrain Gauge Displacement Sensor | Linear Position Sensor | AML/SGD

0-5mm to 0-100mmFrom £425Buy Online